|

|

Build of a Steve Bage EDF MIG17 enlarged to 143%� Chapter 1

By a happy accident at a Prontoprint� facility, Steve Bage�s 17� span MIG17 was

printed as �A3 fit to page� and a 27� version was borne. I had not before

contemplated a scale model but the excellence of the design impressed and I

succumbed to the challenge of producing a free flight electric EDF scale jet,

having never before been tempted by the �scale� discipline. The complexity of the design prompted me to engage Belair

to laser cut 4 off kits for the Peterborough MFC as I was doubtful of my

ability to produce the plethora of intricate formers and wing ribs that

Steve�s design requires. Steve was happy to supply a 143% .dxf file that Belair

needed to laser cut the kits. This was a good decision as the quality of the

cutting was first class. However, the components require some adjustment as

the jigging slots were designed for the smaller 17� model. This is not a

build for the faint hearted and will require some modification of the Belair

supplied components. As supplied

the Belair hardware appear as ��..

Sticking

bits together result in�.

These

assemble as���.

Discussion The plan calls for cutting the fuselage in half at the F7

junction to get access to the EDF. I was nervous about doing this , so I cut

the fore and aft dorsal K1A member to achieve the same. Having witnessed the state of a colleagues paper inlet and

outlet ducts in damp weather, I am not going to use paper. I have ordered

some clear acrylic from [email protected]

to act as formers and I intend to plagiarise the gummed brown paper technique

to build the ducting, described in the Free Flight Forum papers 2011. This

can be damproofed using Johnsons Klear. The parts assemble easily bearing in mind that the jig

slots were oversize having used sheet thickness as per the 17� original. The

method of wing retention is unique and esoteric, needs careful fitting but

works well. I did however CA in a couple of magnets at the root rib. Weight achieved

Airframe

Fuselage (90% complete)�������������� ���������������������������������� 39.2gm Stab��������������������������������������������������� ���������������������������������� 4.1gm Fin����������������������

������������������������������������������������������������������5.0gm Wing right����������������������������������������������������������������������������

11.0gm Wing left������������������������������������������������������������������������������

10.9gm � TOTAL����������������������������������������������������������������������������������

70.2gm For a complete wood only airframe����������������������������������� 78gm Allowing 20% for covering and finish��������� ����������������������� 93.6gm Assume 100gms for safety and self kidding��������� Power system

AEO 6000 kv 44mm EDF with brushless outrunner�������� 36gm Kpaero Mk1 E30 controller with 2mm gold connectors��� 2gm ���������������������������

Suppliers performance figures

Voltage���������� Current���������� Thrust������ Energy (volts)����������

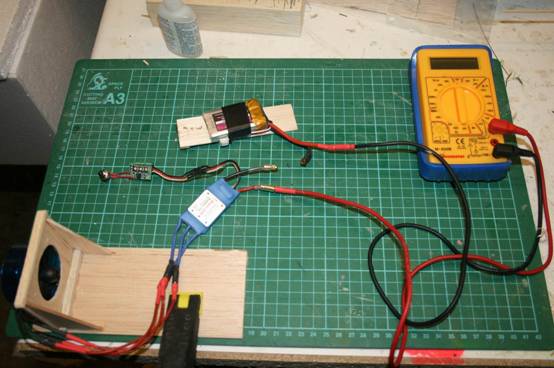

(amps)��������� (gm)��������� ( �� 10��������������� 20.7������������ 328����������� 207 �� 11.1������������� 23.7������������ 374������������ 263 �� 12.6������������ 28.5������������ 436������������ 359 These figures are outrageous and I knocked out a test rig

to see what the unit was really capable of. I used an E30 kpaero controller

with a �wait to start� feature achieved with a push button to the right of

the controller.

44 mm AEO

EDF test rig

44mm AEO EDF

on test Voltage���������� Current���������� Energy (volts)������������� (amps)����������� ( 7.4������������������ 11.2��������������� 82.8 11.1��������������� 18.4��������������� 204 The

suppliers figures are generous but not that far off. Assuming 1.8 gm/Watt of thrust a 2 cell pack will give

149gm thrust. A 3 cell pack will give over 363 gms of thrust ! (Way too

much) (Pay not too much attention to static

thrust figures, a decent forward speed works wonders as does� good inlet and outlet ducting. At model

sizes its not a science but an art). A Hyperion G3 2 cell 550 mah is 65 x 18 x 15mm and will

fit nicely within the battery bay and weigh 32gm for 13.7 amps (25C). A Hyperion G3 3 cell 850 mah is 73.5 x 25.8 x 18.6mm and

will require mods to the battery hatch to fit. It will weigh 69gm and offer

21amps (25C) The 2 cell might be underpowered but nevertheless it�s the

one I am going for. I will team this with a 19gm basic Robotbirds ESC capable

of 25amps continuous. This recognises I might be wrong on the required thrust

allowing a 3s battery change to get out of trouble. For a 2s battery I could

fit a 12amp ESC and lose 6gm���not worth the effort. Hence power unit weight will be� :- EDF��������������� ������ ���������������������������������������������������� 36gm Kpaero controller����������������������������������������������������� 2gm Loom, connectors, switches�������� �������������������������� 15gm Total��� power unit weight����������������������������������������� 85gm Total model weight��������������������������������������������������� 185gm Thrust on 2s�������������������������������������������������������������� 149gm

(Is this enough?) Going 3 cell will be overkill and will add 37 gm to the

AUW, probably destroy the balance and put the AUW to 222gm. Try the 2s , it

might be OK. Look out for Chapter 2 when I have made the ducting and

installed the power unit. |