|

|

|

Home Technical

|

Thermo Formed Depron Wings The article was "Portugeuse Tiger Moth", about a 1/20th scale Tiger Moth but this dodge for forming Depron was worth repeating on its own. Taken, with thanks, from the August 2011 edition of RC Micro World - a .pdf publication available on line and as a subscription from the USA. To see the latest RC Micro World and read about their subscrition scheme click here.

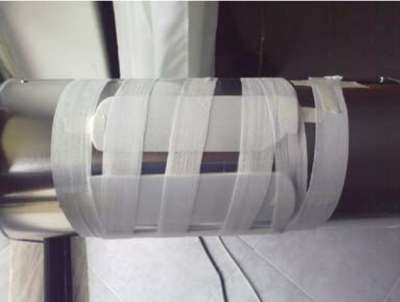

The Depron pieces are fixed to the jig using a few bits of sticking tape, followed by a gauze bandage. I use a bandage, as the hot water does not affect it, and it does not mark the surface. The best part is that one can mould 6mm wings this way, something that is nearly impossible with a heat gun. In fact, the picture above is of a 6mm one (a 1/10 Bristol Scout lies somewhere in future… but the technique is the same for the 3mm one.

Then, rotate the cylinder so the Depron piece lies in the hot water that has accumulated in the bottom of the bathtub, and let it cool there. When the water is lukewarm, it is time to take it away and the panels are ready for use. The 6mm ones might need a second dose of the hot water 'treatment'. Arnaldo Correia |

Some have used

heat guns to mould Depron but I did not like it, as the temperature is hard to

control (one can actually melt the Depron) and the curvature is difficult to

judge/reproduce accurately. So I decided to use hot (near boiling) water, the

bathtub, and a thin metal jig - a 20cm diameter aluminum tube, the kind used

here for air conditioning ducting.

Some have used

heat guns to mould Depron but I did not like it, as the temperature is hard to

control (one can actually melt the Depron) and the curvature is difficult to

judge/reproduce accurately. So I decided to use hot (near boiling) water, the

bathtub, and a thin metal jig - a 20cm diameter aluminum tube, the kind used

here for air conditioning ducting.  I boil about 5

litres of water in a pan (or a kettle - what matters is the quantity, not the

utensil). When the water is boiling, I take the pan and pour the boiling water

slowly and as evenly as possible - to and fro, a few times. I try to warm the

whole piece of Depron so hopefully, it is all at the same temperature. The

water is applied to one side only - the upper surface, so to speak - but it is

enough.

I boil about 5

litres of water in a pan (or a kettle - what matters is the quantity, not the

utensil). When the water is boiling, I take the pan and pour the boiling water

slowly and as evenly as possible - to and fro, a few times. I try to warm the

whole piece of Depron so hopefully, it is all at the same temperature. The

water is applied to one side only - the upper surface, so to speak - but it is

enough.