|

|

||||||

|

Home Technical

|

Aerofoils and Curves in Depron

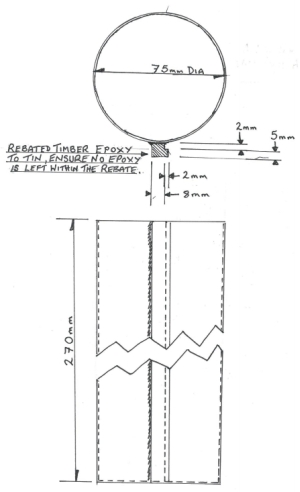

After messing about with various ideas I came up with the following system. I found a long tin 270mm long ( 10inches ) X 75mm Dia ( 3inch ) , I cut a 8 x 10mm hard wood the length of the tin and cut a 2 x 2mm rebate in one edge and used epoxy to glue this to the tin, ( see attached sketch) , Cut the wing to desired length and cord, if using 1mm Depron use a 1mm packing piece to ensure the wing is tight against the tin surface ( packing not required if using 2mm Depron )Fill with Hot water and wearing suitable gloves ( I use thick gardening ) slowly bend the depron around the tube until you get the desired curve, hold for about 30 seconds and remove from tin . Using the method I have formed several wings from 50mm cord to 100mm and 500mm to 600mm span. If you do not have a suitable tin you can use copper pipe etc provided that you can seal one end, a larger dia will produce a smaller curve and a smaller dia will produce a larger curve. You will need to experiment to obtain the aerofoil you require, I have found this method to be quite easy to produce good profile wing sections. WARNING, THIS METHOD IS DANGEROUS, ENSURE NO ONE IS AROUND YOU WHILE DOING THIS.

|

||||||

Having recently returned to Indoor model

flying after a gap of some 15years I have been amazed by the advances in

materials and technical items available. As it have been over 40years since I

built a stick and tissue model I decided to build with the new Depron material,

building the fuselage was fine but forming the wing was not so easy, I tried

bending over a curved table edge, baking over a mould in the oven, and wrapping

around a tube with bandages and immersing in hot water, none of these were

successful, the best results were the bandage trials but not perfect.

Having recently returned to Indoor model

flying after a gap of some 15years I have been amazed by the advances in

materials and technical items available. As it have been over 40years since I

built a stick and tissue model I decided to build with the new Depron material,

building the fuselage was fine but forming the wing was not so easy, I tried

bending over a curved table edge, baking over a mould in the oven, and wrapping

around a tube with bandages and immersing in hot water, none of these were

successful, the best results were the bandage trials but not perfect.